Taron

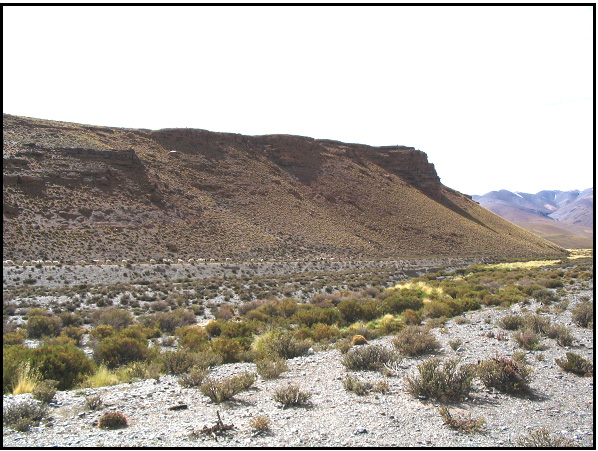

TARON OUTCROP PHOTO LOOKING SOUTH EAST

THE OUTCROP AREA SHOWN IS ONLY A FRACTION OF THE DEPOSIT AND SHOWS A RELIEF OF 70 METRES FOR SCALE. THE WHITE SPOTS SEEN AT THE MID-LATITUDE ARE GRAZING SHEEP.

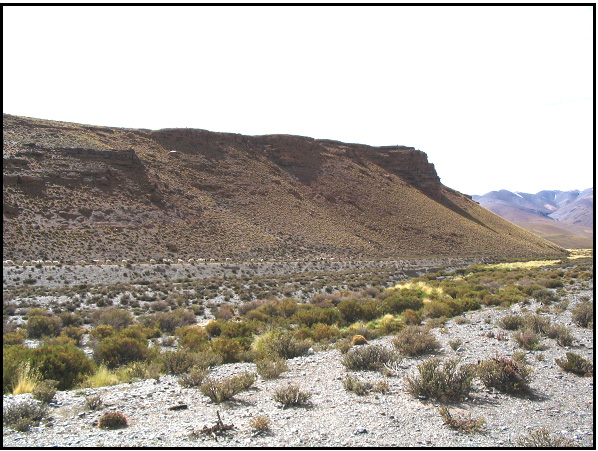

TARON OUTCROP PHOTO LOOKING SOUTH EAST

THE OUTCROP AREA SHOWN IS ONLY A FRACTION OF THE DEPOSIT AND SHOWS A RELIEF OF 70 METRES FOR SCALE. THE WHITE SPOTS SEEN AT THE MID-LATITUDE ARE GRAZING SHEEP.